Basic Electrical Safety

Fire Due to Poor Connections

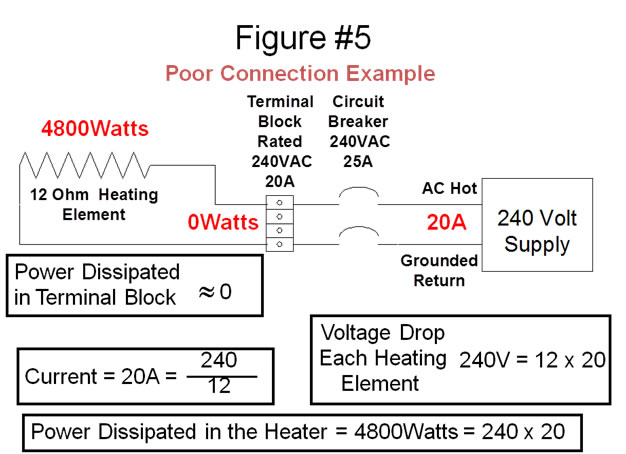

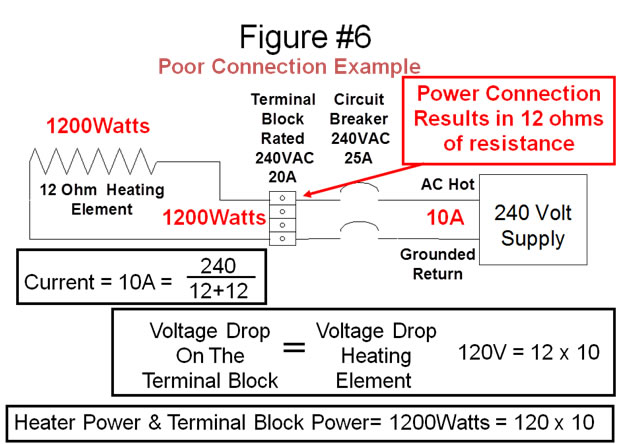

Some of the most common causes of industrial fires are poor electrical connections. They are also one of the most difficult kinds to protect against. If electrical connections are well made they will have very low resistance. In fact electrical design engineers will usually consider their resistance to effectively be 0. This assumption is valid when connections are properly made. However, if a wire connection is loose and the electrical contact surfaces between the two conductors are not tightly made, the resistance in a connection point can be significant. An examination of the simple circuit in Figure #5 and Figure #6 illustrates this point.

Figure #5 shows the circuit functioning as it was designed, the circuit draws 20A and all power is dissipated in the heater. Figure #6 shows the same circuit when a poor connection is made at the terminal block.

The terminal block now has 12 ohms of resistance as a result of the fault, and it in effect functions as an unanticipated heating element. The terminal block and its installation in the system was not designed to handle the 1200 watts of thermal energy that is being generated in it. With this type of extreme elevated temperatures, the terminal block itself can become a source of fuel. This example also illustrates the fact that this type of fault can be obscured by the common protection of properly sized overcurrent protection. Before the fault in this example, the circuit was drawing 20A and after the fault it was drawing 10A – a properly sized circuit breaker will not detect this type of fault. Proper torque applied to the connection is one common way to avoid this problem in new equipment. Other types of electrical connections have similar solutions such as ensuring proper crimping for crimp connector assembly. A more difficult problem is that this type of problem can manifest itself over time. Normal operation and vibration of equipment can loosen connections over a period of years, causing this type of problem. Companies often enact a policy of annual thermal scans of power distribution panels to detect elevated temperatures indicative of problem connections before they can cause problems. A preventative measure such as this can help reduce the risk of a major facility fire.